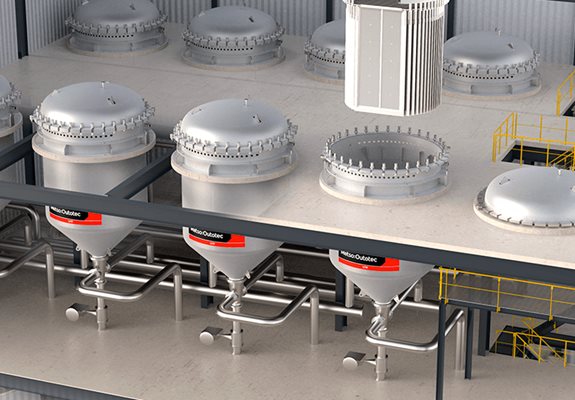

Metso VPFs operate in parallel to remove the remaining solids from the pregnant liquor of the mud settler overflow before it enters the precipitation phase. The filtration process is controlled by a separate PLC-based system.

The mud settler overflow is fed into the filter element from the bottom of the filter through the filter cloth. A filter aid is used to form a porous layer above the filter cloths. The filtrate exits from the top of the filter through the outlet manifold and cake forms on the outer surface of the filter element. At the end of the filtration cycle, when the feed flow falls below the minimum set point, one filter at a time is cleaned while the others continue to operate.

Stable, reliable performance

The automatic cloth cleaning and cake discharge steps at the end of each filtration cycle ensure maximum filtration time in subsequent cycles and remove the need for personnel to perform these actions. Metso VPFs are delivered as fully automated systems with sequence control for multiple filters and can be fully integrated with your plant automation system.

Safe to operate and maintain

The filter vessel remains securely closed and sealed for the entire duration of the filtration cycle, including during the cloth cleaning and cake discharge steps. The shell flange is located just one meter above the operating platform to enable safe, easy inspection and maintenance access. Filter leaves can be removed and replaced as a single cartridge using an overhead crane to transfer the leaves to and from the cloth dressing station, which is located close to the filters to minimize filter downtime.

Low CAPEX, operating, and maintenance costs

The space-efficient design, which eliminates the need for additional small filter vessels around the main vessel, maximizes the area available for filtration within the footprint of the filter system.

With a long filtration cycle of up to 18 hours, the off-line time for cloth cleaning and cake discharge is minimized, as is the consumption of filtration aid. Product loss is minimized by recovering the solution content of the filter before the cake discharge sequence starts. In addition, the absence of moving parts minimizes the maintenance cost per cubic meter of produced filtrate and reduces the number of wear parts that need to be replaced during the filtration system’s life cycle.

The unique cloth cleaning and cake discharge system together with the integral caustic washing step ensures maximum filter cloth lifetime.

Proven technology

Metso VPF technology, originally developed by Australian Process Technology in 1979, is the technology of choice in several Australian alumina refineries. Customers selecting this solution can benefit from Metso’s world-class know-how, technical support, and start-up and training services for supersaturated sodium aluminate solution security filters.